Inspiring the world of fashion through design, technology and innovation by means of an ethical and sustainable production of chains and accessories in non-precious metals, as style complement of fashion creations for leather goods, footwear, clothing and fashion jewellery.

Centro Stile

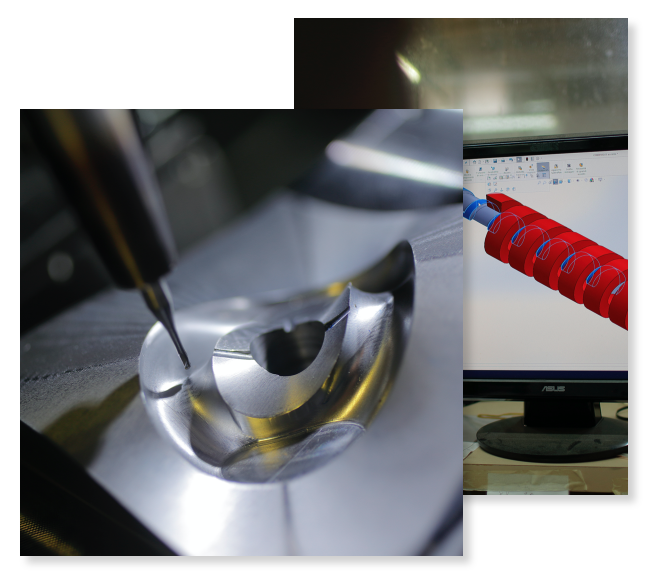

From design to first prototype production. This is the beating heart of M4F: the place where designers’ creative ideas are brought to life with the support of technology, and where product and first prototypes are developed. Innovative 3d rendering and CAD systems are devoted to the creation of custom-made chains and accessories.

Materials

For us, stainless steel, aluminum, brass, bronze are not only materials but are the subject of our continuous research and innovation. We believe that the processes and materials used during the manufacturing cycle, play a crucial role in building a sustainable future. For this reason, we have decided to increase our production of chains in stainless steel: an eco-friendly metal, deemed to be the green product of the future.

Mechanics

With more than 500 wire processing machines that can be adapted to the needs of our customer, we are able to offer a wide choice of models, design flexibility and a large production capability.

Most of the machines and technology adopted in each manufacturing process are planned, designed and built in-house by ICM, the technological division of the group.

Robotics

Our Hi-tech equipment, which includes collaborative robots, rapid prototyping machines with 3D printers, allows us to develop and produce, customised elements for chains and accessories, while ensuring a consistently high-quality result in case of large volume orders.

Job Platers

Thanks to the recently merged in-house job plater CRIVAL Galvanica, we are able to provide finished-to-end articles, with galvanic treatment and e-coating.

Sustainability

For us at m4F, the respect of our environment has always been a deep commitment as well as the most important of our guidelines. Today, the continuous improvement involves all the production units through an appropriate policy of energy saving and use of renewable sources. We also pay particular attention to the increase and optimization of solid waste disposal, as well as to the recycling of waste

M4F supports emerging talents

We are fascinated by young emerging talents who can bring a new fresh and surprising vision to the fashion scene, and we proudly share their expectations and insights by supporting them in the realization of their creations.

In 2020, we provided Mr. Andrea Brocca – a promising designer – with our chains for the creation of his graduate fashion collection for the Central Saint Martins School of London.

Certification

We have recently introduced a certified integrated management system for quality, safety, and environment (ISO 9001 – ISO 14001 – SA 8000) as a strategic corporate choice.